Background

Lapping and Polishing

Conventional Liquid Slurry Wafer Polishing Is Slow

Conventional abrasive liquid slurry polishing systems can not be operated at high speeds because the liquid-wetted wafers will hydroplane. When the wafers hydroplane, they “raise up” and loose contact with the very tiny abrasive particles coated on the revolving platen. Then, no wafer abrading takes place.

Use of the fixed-abrasive island discs allow water-spray wetted wafer abrading to occur at high speeds without hydroplaning

Diamonds Cut Sapphire, SiC and GaN

Sapphire, SiC and GaN are almost as hard as diamond. However, when diamond abrasive particles are used to abrade these hard materials at very high abrading speeds, the diamonds provide very high wafer cut rates.

Precision-Flat, Smoothly Polished Wafers Required

Logs (boules) of single-grain grown sapphire, SiC and GaN are rough-sliced into wafers that must be precisely flattened and polished..

Cut Rates Increase With Speed

Wafer cut rates increase directly with increased abrade speeds.

Conventional slow-speed liquid abrasive slurry abrading has very low wafer cut rates. It can not be speeded-up because of wafer hydroplaning.

High-speed fixed-abrasive island discs provide very high wafer cut rates without hydroplaning.

Vitrified Diamond Abrasive Agglomerates, Long Disc Life

Vitrified diamond abrasive agglomerates consist of diamond particles encapsulated in glass. The glass rigidly supports individual diamond particles against abrading forces.

The agglomerates are molded into island shapes that are bonded to flexible disc backings. The islands prevent hydroplaning.

These high-speed island discs are durable, have large cut rates and last a long time abrading sapphire and other hard materials.

High Speeds Cause Hydroplaning

When a wafer contacts a liquid abrasive slurry coated abrading surface moving at high speeds, the wafer hydroplanes. Upon hydroplaning, the wafer is forced by hydraulic pressure away from the abrading surface with a reduction in cut rates.

One analogy is high speed hydroplaning of a boat.

Another analogy is high speed hydroplaning of bald car tires on a water-wetted highway. Car tires with tread lugs (disc islands) do not hydroplane.

Abrasive island discs do not hydroplane at high speeds. The islands prevent the formation of thick layers of water that separate the wafers from the abrasive surface.

Platens Require Annular Bands of Abrasive

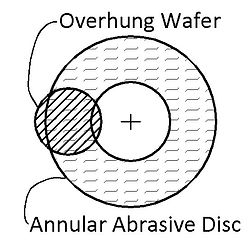

The radial width of the annular band of a platen coated with abrasive is slightly less than the width of the abraded wafers in abrading contact with the platen abrasive. This allows the wafers to overhang both the inner and outer radii of the abrasive during abrading.

Rotating both the platen and wafers in the same direction and at the same speed allows both the wafers and the platen abrasive to wear down uniformly and maintain their flatness.

Both liquid slurry and island disc abrading systems use annular bands of abrasive.

Liquid Abrasive Slurry VS Fixed Abrasive

LIQUID ABRASIVE SLURRY COATED ON PLATEN

A liquid abrasive slurry is continually applied to a rotating flat platen surface while a rotating wafer is in flat-surfaced contact with the platen abrasive. The abrasive particles remove the high spots on the wafer. However, the platen surface becomes non-flat as the wafer wears a groove in the platen due to the loose abrasive particles between the wafer and the platen when the platen moves relative to the wafer. Platens are periodically reground to restore their flatness. The platens must rotate slowly at about 50 rpm to prevent hydroplaning of the wafers. Cut rates are very low because of the slow speeds.

CMP PAD SATURATED WITH LIQUID ABRASIVE SLURRY

Soft and resilient CMP fiber pads attached to a rotating platen are continually saturated with a liquid abrasive slurry. A

rotating wafer is then plunged into the depths of the moving resilient pad to abrade the wafer. Distortion of the soft pad, particularly at the leading edge of the wafer, causes non-uniform abrading of the wafer surface. Material removal is greatest at the outer surface of the wafer.

The wafer is attached to an elastomer bladder that has from 3 to 8 radial abrasive pressure zones to compensate for the abrading cut rate variation on the wafer. Controlled pressures vary from 3 to 9 psi in each radial zone during the abrading event depending of process recipes developed for specific wafers and machines. The abrading speeds are very slow and the wafer cut rates are very low.

Crusts of dried abrasive slurry and wafer debris forms on the CMP pad surfaces. Jagged diamonds attached to a plate are used to periodically break up the crusts to restore the abrading action of the pads.

FIXED ABRASIVE DISCS WITH SQUARE ELEMENTS

3M diamond Trizact tile discs having patterns of adjacent shallow square abrasive tile elements are attached to rotating platens and rotating wafers are held in flat-surfaced abrading contact with the disc abrasive. These discs do not have the annular bands of abrasive that are required to provide uniform wear-down of the disc abrasive by wafers that overhang the abrasive annular bands.

FIXED ABRASIVE GRINDING WHEELS

Grinding wheels with narrow annular bands of serrated abrasive are used to abrade wafers and workpieces. The small

leading edge arc segment surface contact areas of the narrow annular abrasive results in high abrading pressures. They have very high cut rates with coarse abrasives but leave wafer rough surfaces, micro-cracks and subsurface damage. Another grinding wheel with fine abrasives is then used to remove the wafer surface damage. CMP abrading or lapping can then be used to provide a smooth surface.

FIXED ABRASIVE HIGH_SPEED ISLAND DISCS

Flexible discs with annular bands of abrasive islands attached with vacuum to platens allow the abrasive particle sizes to be quickly changed. The islands prevent hydroplaning of water spray cooled wafers at high abrading speeds and provide high cut rates. Low abrading pressures are used to eliminate wafer damage.

Non-Flat Worn Platens

With the conventional liquid abrasive slurry polishing system, abrasive particles are mixed with oil or water and applied to a rotating platen that is in flat-surfaced contact by abraded wafers. As the abrasive slurry is positioned between the wafers and the platen, both the wafers and the platen surfaces are abraded, making the platen surface non-flat.

Wafers are contained in fixed-position conditioning rings that continually abrade the platen surface to maintain its flatness.

The flatness of the platen surface is periodically measured. When out-of-spec, the platen surface is re-ground to make it flat again. The typical non-flat variations of a platen surface far exceeds the sizes of the micron-sized abrasive particles used to polish the wafers.

By comparison, the precision-flat platens used with the flexible island discs remain flat during extensive abrading action. Here, the surface of the platen is protected by the vacuum attached abrasive discs.

Re-Flatten Disc Island Surfaces

When the planar surface of the disc islands becomes non-flat, it can quickly and easily be re-conditioned.

Here , the wafer disc that is attached with vacuum to the wafer head is replaced with a standard aluminum oxide abrasive disc having the same diameter as the wafer disc. The rotating abrasive disc on the wafer head is then used to abrade flat the rotating disc islands.

Abrading Friction Heats Wafers

Heat produced by abrading friction must be removed to prevent distortion of the wafer surfaces.

Little heat is generated by slow-moving abrasive slurry. The heat is removed by the liquid abrasive slurry.

More friction heat is generated by the high speed abrading. However, this heat is very effectively removed from the wafer surfaces by use of a water spray applied to the moving disc surface. Very high heat transfer occurs with evaporation of the water film spread on the wafer surface by the porous bead filler located between the islands.

Change Abrasive Particle Sizes

The sizes of the abrasive particles are typically changed three times when abrading wafers. Large-sized particles are used to initially flatten the wafer. Medium-sized particles are used to rough-polish them and small particles provide a smooth surface.

Changing particle sizes with liquid abrasive slurries is messy and time consuming. All of the previous large-sized particles must be completely removed from both the wafers and the platen before the smaller-sized particles can be used. Contamination of the small particles with stray large-sized particles disrupts the polishing action.

Island discs, having fixed-abrasives, that are vacuum attached to a platen can be quickly changed with little clean-up required. The wafers remaining attached to the wafer head can be simply washed with water to remove stray large particles before the next phase of polishing.

Compare Changing Abrasive Particle Sizes

-

LIQUID ABRASIVE SLURRY:Messy,Slow

-

PSA ADHESIVE DISCS:Slow, Difficult

-

HOOK & LOOP DISCS:Non-Flat Abrasive, Not Rigid

-

VACUUM DISCS:Quick

High Speed Agglomerate Abrasive Island Discs

Vitrified diamond abrasive agglomerates are molded into islands bonded in annular bands on flexible discs. The island shapes prevent hydroplaning of water-cooled wafers at high speeds.

The diamond-particle agglomerates provide high cut rates of sapphire wafers and long abrade lives of the island discs.

A porous-bead material between individual islands provides a water film that cools the wafer during abrading operations.

Discs range in size from 6”, 12”, 18” and up to 60”, or more.

Porous Abrasive Islands Provide Controlled Wear-Down

The abrasive agglomerate filled islands must be porous to provide a sustained and controlled rate of eroding during wafer abrading. The agglomerates and their diamond particles are continually worn down and replaced.

This eroding action allows wafer high and consistent cut rates to occur as the islands slowly wear down.

Solvent-based phenolic adhesives are used to strongly bond the abrasive agglomerates together in the island structures. As the solvent evaporates during production of the discs, voids are formed, making the islands porous.

Vitrified Diamond Abrasive Agglomerates

Vitrified agglomerates contain diamond particles strongly bonded by glass to resist abrading forces.

During abrading, the glass erodes and exposes individual diamond particles that are continually re-sharpened until each particle is slowly worn away.

This allows full utilization of each expensive diamond particle.

Fully-Utilize Individual Diamond Particles

Only some of the abrasive particles in an abrasive slurry are fully utilized. They are continually supplied in a liquid stream during the abrading operation.

Just the largest particles present on the high-spot areas of the platen are in abrading contact with the wafers. Many of the typical tiny 2.5 micron (0.0001”) diamond particles residing in the platen low-spot areas are not utilized.

Spent slurry, containing old and new particles and abrading debris, is continually washed off the abrading surface of the platen.

By comparison, with the island discs, each individual fixed-abrasive diamond particle encapsulated by glass in the agglomerates is fully utilized as it slowly wears down during abrading.

Percent Diamond Particles In Agglomerates

A wide range of abrading cut rates and disc abrade life can be affected by many variables.

These include: the percent of diamond particle content in the vitrified abrasive agglomerates, the quantity of agglomerates in the islands, the porosity of the islands, the size of the diamond particles, the island disc and agglomerate manufacturing processes, the abrade speeds and the abrade pressures.

High Speed Abrasive Lapper Machine

Flexible abrasive island discs are quickly attached to a platen by vacuum to allow wafers to be polished at high abrading speeds. An air-bearing platen having a 0.0001” precision-flat surface allows abrasive discs up to 18” diameters to be used interchangeably at speeds up to 3,000 rpm.

The wafers are quickly attached with vacuum to a wafer head to provide flat-surfaced conformal contact to the platen abrasive surface. Both the wafers and the platen are rotated in the same direction and about the same rpm to obtain uniform abrading of the workpieces and uniform wear of the disc abrasive.

Post-Wheel Lapper VS Liquid Slurry Machines

The post-wheel abrasive lapper machine utilizes the best features of both a high-speed lapper machine and those of a slow-speed liquid slurry machine. Both systems allow the rotating wafer to have rolling contact with a cylindrical support.

The slow-speed slurry machine uses a self-rotating floating wafer ring that is held in place by two stationary idler rollers that are attached to a machine frame. A loose wafer is contained by the wafer ring that is rotated by differential friction from the rotating platen. Options for applying an abrading force are limited.

The simple post -wheel lapper machine also utilizes the concept of rolling contact of a wafer. It has a fixed-position rotating contact wheel in rolling contact with a recessed hole at the center of the floating wafer holder plate. The floating wafer plate can be rotated at high speeds where the wafer remains in flat-surfaced contact with the rotating platen abrasive. Also, controlled air pressure in an internal chamber applies uniform abrading pressure across the full abraded surface of the floating wafer during a wafer polishing operation.

Verified Island Disc Sapphire Abrade Test Data

High speed sapphire abrading test data of Keltech vitrified diamond agglomerate island discs using 40-50 micron and 30 micron diamond discs have shown 10X to 50X faster cut rates.

The test data and test conditions are described in the TECHNOLOGY and DATA sections.

Low-Speed Island Discs For Existing Slurry Lapping Machines

“Soft” diamond abrasive agglomerates are used to make island discs that erode easily at low speeds and low abrade forces. These fixed-abrasive discs can be used on the many existing slurry lapping machines.

“Soft” Agglomerates Erode Easily

“Soft” diamond abrasive agglomerates are used to make island discs that erode easily at low speeds and low abrade forces. These fixed-abrasive discs can be used on the many existing slurry lapping machines.

Mold-Formed Abrasive “Cube” Agglomerates

Small abrasive cube agglomerates can be made in a mold using solvent-based adhesives to provide porous cubes that erode easily. Epoxy based abrasive cubes can replace vitrified split agglomerates produced in a high temperature furnace.

Use Abrasive Island Discs with CMP Slurry System

Sliced silicon and very hard sapphire, SiC and GaN wafers can be quickly flattened and polished with Keltech’s abrasive island discs at high abrading speeds in preparation for CMP slurry polishing.

Then, the loose-abrasive slurry particles can be used to finish-polish the wafers using the slow CMP process.

Use CMP Chemicals With Island Discs

The chemical additives used to “soften” the surfaces of wafers for faster CMP abrading can also be used with the abrasive island discs.

These chemicals can be simply added to the coolant water that is sprayed on the island disc when abrading wafers.

Cut Rate Variables

3M Fixed-Abrasive Diamond Tile Discs

3M Diamond Tile discs do not have annular bands of abrasive. Wafers can not overhang the abrasive to provide uniform wear-down of both the wafers and the disc abrasive during abrading operations.

Keltech’s fixed-abrasive vitrified diamond island discs have annular bands of islands. The radial width of the island bands are less than the width of the wafers which overlap both the inner and outer annular diameters of the bands.

Semiconductor Wafer Thinning

Semiconductor wafers typically have a 0.030” thickness to provide enough stiffness to be handled during the many process steps of creating the integrated circuits.

After completion, the wafers are abraded to reduce the wafer thickness to about 0.002” . Thin diced semiconductor chips have better cooling and can be stacked to form 3D devices.

Wafer thinning is often done sequentially by two methods. First, grinding wheels with coarse and then fine abrasive provide fast cut rates that remove most of the wafer thickness but still can leave a rough surface that has micro-cracks and subsurface damage.

Next, CMP pads with a liquid abrasive slurry are used to polish the wafers. The CMP material removal process is very slow but provides a smooth wafer surface that is free from micro-cracks and sub-surface damage.

High-speed abrasive island discs with coarse and then fine abrasives can also be used to provide fast cut rates and eliminate both micro-cracks and subsurface damage.

Automated Wafer Thinning

Wafer semiconductor surfaces can be bonded to carrier plates with a UV removable tape. Wafers stored in a cassette rack can be sequentially transported to a high-speed abrasive island disc wafer thinning station. After wafer abrading and cleaning, the UV tape is removed.

Reduced Machine Mass

Providing precision flatness of machine components is required to produce flat-surfaced wafers. When large

abrading forces used for slow- abrading are imposed on wafers, the machine components tend to distort. Distortion

causes non-flat wafers. To minimize component distortion, the machines are constructed with heavy and stiff

components.

Use of high-speed abrasive island discs allows the abrading forces to be substantially reduced but still provide the

same cut rates. The high-speed machines have less mass and stiffness but successfully provide the required

precision-flat wafers.

Vitrified Diamond Agglomerate Abrasive Wheels

The vitrified diamond agglomerates can be mixed with a solvent-based adhesive and coated on a wheel hub.

As the solvent evaporates, voids are formed in the mixture to form the required porous adhesive layer.

The adhesive strongly supports each individual agglomerate and the agglomerates support the individual diamond abrasive particles.

Vitrified Diamond Agglomerate Non-Island Abrasive Discs

Vitrified diamond agglomerates can be coated with adhesives on the surface of polymer discs or on continuous webs. Abrasive sheets, strips or discs can be cut from the webs.

Pre-vitrified diamond abrasive agglomerates are simply coated on the polymer backing discs (or webs) using conventional coating processes and solvent-based adhesives.

Evaporation of solvent from the adhesives during curing produces the void spaces between individual agglomerates.